Abolhasani and Genzer Group Researchers Develop a ‘Green’ Technique to Boost Pharma Manufacturing Efficiency

About 70 percent of pharmaceuticals are manufactured using palladium-driven catalytic processes that are either fast or efficient – but not both. Collaborating researchers in the Abolhasani and Genzer research groups have developed a green chemistry method that combines aspects of both types of processes to improve manufacturing efficiency with a minimal cost of processing time.

In homogeneous processes, palladium is dissolved in solution, allowing maximum exposure to the organic molecules, or reagents. This makes the process very fast, but results in a lot of palladium either being wasted (because it gets thrown out after target molecules are harvested) or being recovered at high cost (because the recovery process is expensive).

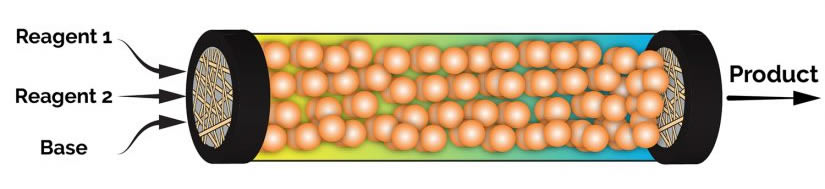

In heterogeneous processes, palladium is fixed to a hard substrate in a packed-bed reactor, and the reagents are run through the reactor. This takes much longer, but little or no palladium is wasted.

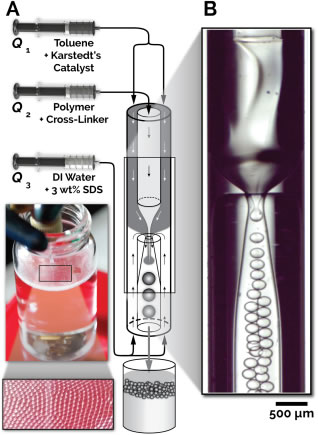

“We’ve created and tested a new process called pseudo-homogeneous catalysis, which combines the best of both worlds: it is nearly as fast as homogeneous catalysis, while it preserves virtually all of the palladium,” says assistant professor and corresponding author of a paper on the work, Dr. Milad Abolhasani. The new technique relies on novel, elastic silicone-chemistry based microspheres developed by the research team using microfluidics.

“We used a microfluidic strategy to make elastomeric microspheres with a narrow size distribution to make them ‘loadable’ into a tubular reactor without clogging,” Abolhasani says. “That was essential, because conventional batch scale polymerization techniques result in elastomeric microspheres with a large size distribution that would clog the reactor when loaded.”

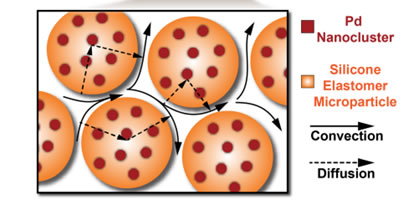

Each silicone microsphere is loaded with palladium. Reagents then pass through the microsphere and interact with the palladium. The resulting pharmaceutical target molecules leave the microsphere again – but the palladium remains trapped in the microsphere.

“The flexible spheres allow the palladium catalyst to ‘settle’ inside the microreactor environment,” says Dr. Jan Genzer, the S. Frank and Doris Culberson Distinguished Professor of Chemical and Biomolecular Engineering and a co-author of the paper. “The flexibility of the silicone sphere allows the palladium catalyst to adopt very many configurations during the reaction – as is the case in homogeneous processes. The palladium catalyst is retained for further use – as is the case in heterogeneous processes.”

“In proof-of-concept testing, our process was much faster than any heterogeneous techniques, but still marginally slower than conventional homogeneous processes,” Abolhasani says. “We’re currently working on optimizing the properties of our elastic microspheres to improve the reaction yield.”

One other important advantage of the pseudo-homogeneous technique is that it makes use of nontoxic solvents, i.e., water and ethanol. Conventional homogeneous techniques typically use organic solvents, such as toluene, which are not environmentally benign.

“It is important to demonstrate that green chemistry approaches can be used to make a process that is, in all, more efficient than existing techniques,” Abolhasani says. “You do not have to trade safety for cost-effectiveness.”

The paper, “Microfluidic Synthesis of Elastomeric Microparticles: A Case Study in Catalysis of Palladium-Mediated Cross-Coupling,” is published in the AIChE Journal. The paper was co-authored by Jeffrey Bennet, a Ph.D. student in Abolhasani’s lab; Andrew Kristof, an undergraduate at NC State; Vishal Vasudevan, a visiting undergraduate at NC State; and Jiri Srogl, a CBE adjunct associate professor.

The original article was written by Matt Shipman, Research Lead in University Communications at NC State.

- Categories: