Dickey Group Develops ‘Soft Tactile Logic’ That Distributes Decision-Making Throughout a Stretchable Material

This article is a slightly modified version of an article written by Matt Shipman, Research Lead in University Communications.

Inspired by octopuses, Professor Michael Dickey and his colleagues have developed a structure that senses, computes and responds without any centralized processing; creating a device that is not quite a robot and not quite a computer, but has characteristics of both. The new technology holds promise for use in a variety of applications, from soft robotics to prosthetic devices.

“We call this ‘soft tactile logic,’ and have developed a series of prototypes demonstrating its ability to make decisions at the material level – where the sensor is receiving input – rather than relying on a centralized, semiconductor-based logic system,” says Prof. Dickey, co-corresponding author of a paper on the work and Alcoa Professor of Chemical and Biomolecular Engineering.

“Our approach was inspired by octopuses, which have a centralized brain, but also have significant neuronal structures throughout their arms. This raises the possibility that the arms can ‘make decisions’ based on sensory input, without direct instruction from the brain.”

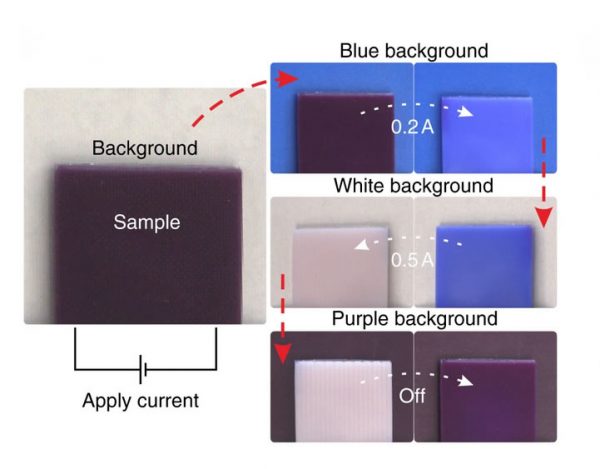

At the core of the soft tactile logic prototypes is a common structure: pigments that change color at different temperatures, mixed into a soft, stretchable silicone form. That pigmented silicone contains channels that are filled with metal that is liquid at room temperature, effectively creating a squishy-wire nervous system.

Pressing or stretching the silicone deforms the liquid metal, which increases its electrical resistance, raising its temperature as current passes through it. The higher temperature triggers color change in the surrounding temperature-sensitive dyes. In other words, the overall structure has a tunable means of sensing touch and strain. Video of the technology can be seen here.

The researchers also developed soft tactile logic prototypes in which this same action – deforming the liquid metal by touch – redistributes electrical energy to other parts of the network, causing material to change colors, activate motors or turn on lights. Touching the silicone in one spot creates a different response than touching in two spots; in this way, the system carries out simple logic in response to touch.

“This is a proof of concept that demonstrates a new way of thinking about how we can engineer decision-making into soft materials,” Dickey says.

“There are living organisms that can make decisions without relying on a rigid centralized processor. Mimicking that paradigm, we’ve shown materials-based, distributed logic using entirely soft materials.”

The researchers are currently exploring ways to make more complex soft circuits, inspired by the sophisticated sensors and actuators found in biological systems.

The paper, “Materials tactile logic via innervated soft thermochromic elastomers,” is published in the journal Nature Communications.

First author of the paper is Dr. Yang Jin, a former visiting scholar with Prof. Dickey’s research group and former Ph.D. student at Jiangnan University. Co-corresponding author of the paper is Prof. Mingqiao Ge of Jiangnan University. The paper was co-authored by Drs. Yiliang Lin and Ishan Joshipura, former CBE graduate students; and Dr. Abolfazi Kiani, a visiting professor with Prof. Dickey’s group who is also on faculty at the University of Isfahan in Iran.

- Categories: