Sejong Kim

| PhD, Polymer Science, 2006 University of Connecticut, Storrs, Connecticut M.S., Chemical Technology, 1994 Seoul National University, Korea B.S., Chemical Technology, 1992 Seoul National University, Korea |  |

Research Focus: Super-Stable Foams and Emulsion from Hydrophobic Cellulose Particles via an Environmentally-Friendly Process

Foams and emulsions are thermodynamically unstable or metastable systems consisting of two immiscible phases that, if given sufficiently long time, will separate into two distinct phases. As a practical way to obtain stable foams and emulsions, surface active agents including emulsifier and stabilizer are typically added to provide kinetic stability in the system. Although conventional synthetic molecular surfactants have been already well established and widely applied in various industries, environmentally friendly surface active agents of natural origin are recently of particular interest due to their importance in numerous bulk chemical materials, personal care products and food industry. The formation of particle-stabilized emulsions – so called “Pickering emulsions” – has been first reported in the early 1900s by Pickering, and numerous efforts to understand the behavior and stabilization mechanism of particle-stabilized emulsions have been performed. The interest in solid particulate stabilizers made of non-hazardous materials has been surging in academia as well as industry recently due to their potential application as an environmentally friendly surface active agent, which can possibly substitute conventional synthetic surfactants.

In this project, we utilize liquid-liquid dispersion technique to form super-stable foams stabilized by particles of hydrophobically modified cellulose derivatives, which are non-toxic and edible. The methodology employed in this process is based on a solvent attrition mechanism triggered by solubility change in suspension media. Compared to foams stabilized by small molecular weight surfactant and proteins, the lifetime of foams stabilized by cellulose derivative particles was much longer, and the overwhelming stability will provide tremendous opportunities for a variety of product developers to manufacture foams and emulsions that require long-term stability, which can not be realized by existing molecule-based surface stabilizers. This technique has a great potential in replacing conventional small molecular surfactants and proteins, or in developing super-stable edible or biodegradable dispersion products in food, pharmaceutical and cosmetic industries.

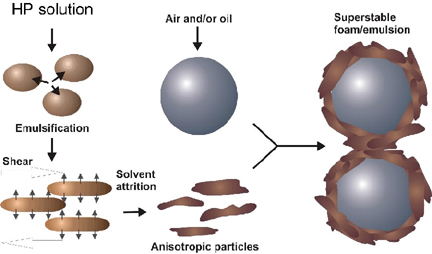

Figure 1: Schematics of the mechanism of forming foams and emulsions stabilized by in situ formed hydrophobic cellulose particles.

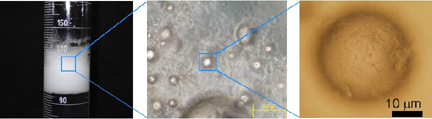

Figure 2: A photo of cellulose particle-stabilized foam (left) and micrographs of individual bubbles (right).

Electric-Field-Controlled Nanofluidics

Flows in molecularly thin films impact coating, lubrication, and microfluidics. In some applications, molecular flows ensure uniform surface coverage, while in others they are used as new tools for surface patterning and for performing biochemical assays on microchips. Typical flow properties have been studied for thick films. However, in molecular/nanoscale thin films there are still many questions unanswered. Recent studies indicate that flow coupled with interfacial interactions has extraordinary effects on macromolecules by inducing fundamental changes in their chemical and conformational structures.

In this project, we explore actuation principles and techniques for manipulation of nano-scale thin fluid layers on solid substrates by using electric fields. Fundamental questions including the electrospreading of precursor films and individual response of polymers or bio-macromolecules to the electric field are being studied.

Figure 3: Schematics of three electrospreading configurations that are used for manipulation of layers of different conductance and substrate interactions.

Publications